Zvatinoita

Star Machining Technology inyanzvi yekugadzira mold, inyanzvi mukuumbwa kwakakura uye kwakaoma, tinopa imwe-stop mold solution, iyo inosanganisira mold component mechanical design, mold design, mold fabrication, plastiki kana casting component kugadzira uye sekondari processing services.

PaStar Machining Technology, isu tine ruzivo rwakadzama rwekugadzira uye kutsanangura kuvakwa kwealuminium kufa kukanda mold uye majekiseni mold.Isu tinotanga kugadzira mold nekukurumidza nekushanda newe kuona kugadzira-kugona kwedhizaini.Isu tichabatsirawo kumisikidza maitiro ekuita kwechikamu chakapedzwa.Uku kumberi kwekubatanidzwa mukufa kukandira mold dhizaini uye kuongorora maitiro kunobatsira kuve nechokwadi chemhando yechigadzirwa.Isu tinokwanisa kugadzira akadzama ekushandisa madhizaini, chikamu chakadhindwa uye zvakatemwa kubva kune yako prototype, kana yako 2D kana 3D CAD mafaera.Vagadziri vedu vanogadzira mold vanokupa zvakanakisa zvepasirese: inotungamira kumucheto maitiro uye zvishandiso mumaoko evane hunyanzvi uye vane ruzivo mhizha.Yedu chaiyo mold dhizaini uye nemazvo ekuvaka kugona anoshandura kuita sisitimu yekugadzira iyo inogadzira zvikamu zvemhando yepamusoro.Paunotumira Star Machining Tekinoroji kuti ivake molds dzako, unovimbiswa zvikamu zvine mashandiro anowirirana uye kudzoka kwakanyanya pakudyara kwako kwekushandisa.

Isu tinonzwisisa zvakare kuti anoratidzwa zvakanyanya, akasimba-kushivirira mativi, ane hukasha ekutungamira, anoda zvemhando yepamusoro zvekushandisa-kubva pakugadzirwa kwekutanga kunoitwa muhupenyu hwechigadzirwa chako.Kunyangwe isu tiri kuvaka mold yeimwe-off prototype kana yakawanda-cavity, yakazara furemu yekugadzira mold, yakasarudzika maturusi iri pamoyo weStar Machining Technology's die casting molding uye jekiseni rekuumba mashandiro.

Yedu Injiniya Mano Anosanganisira:

Chikamu Dhizaini:Isu tinogadzira zvigadzirwa zvinowedzera kudhura-zvinoshanda tooling

Kuyerera Kwekuyerera:Isu tinoita epurasitiki kunyungudika kuyerera kuyerera neMoldex3D

Mold Design:Zvese zvigadziriso zvinogadzirwa uchishandisa Creo Parametric

Tsvagiridzo neMitemo:Isu tinochengetedza raibhurari yezviyero zvevatengi vega

Progress Reporting:Machati uye nguva dzose kufambira mberi kwekuvandudzwa kwakaitwa

Electronic Data Transfer:FTP uye email zvakabatanidzwa zviripo

Chengetedza uye gadzirisa CAD

Mhando dzeMolds dzatiri Kupa

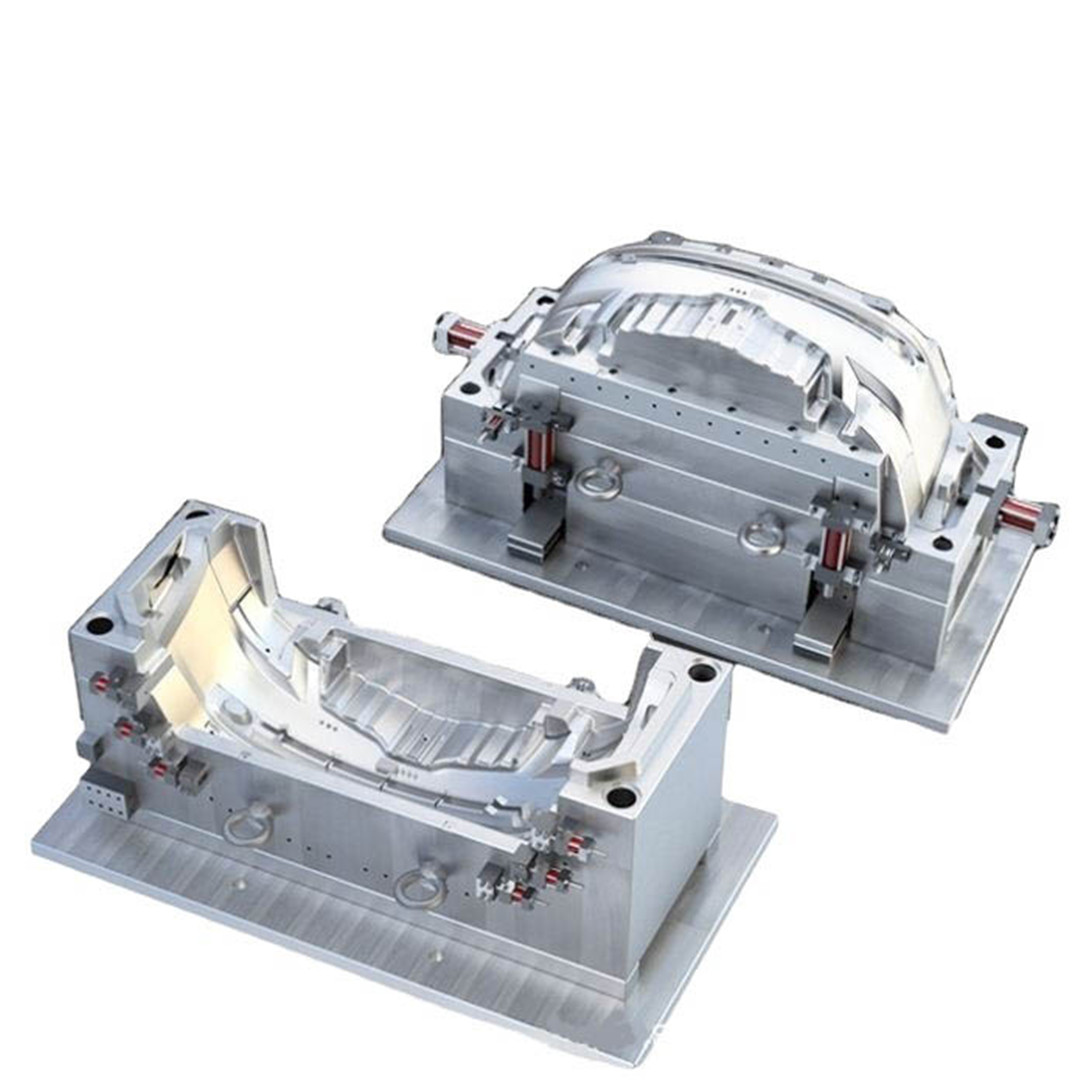

Die Casting Mold

Kusiyana nevazhinji prototyping nyanzvi, isu tinogona kupa simbi yekukanda mold (uye yakaderera-vhoriyamu yekukanda sevhisi kuburikidza nevatinoshanda navo).Aya ma mold - anowanzo gadzirwa kubva kusimbi yakaoma - anogona kushandiswa kugadzira zvikamu kubva kualuminium, zingi, magnesium uye mamwe masimbi asina-ferrous.

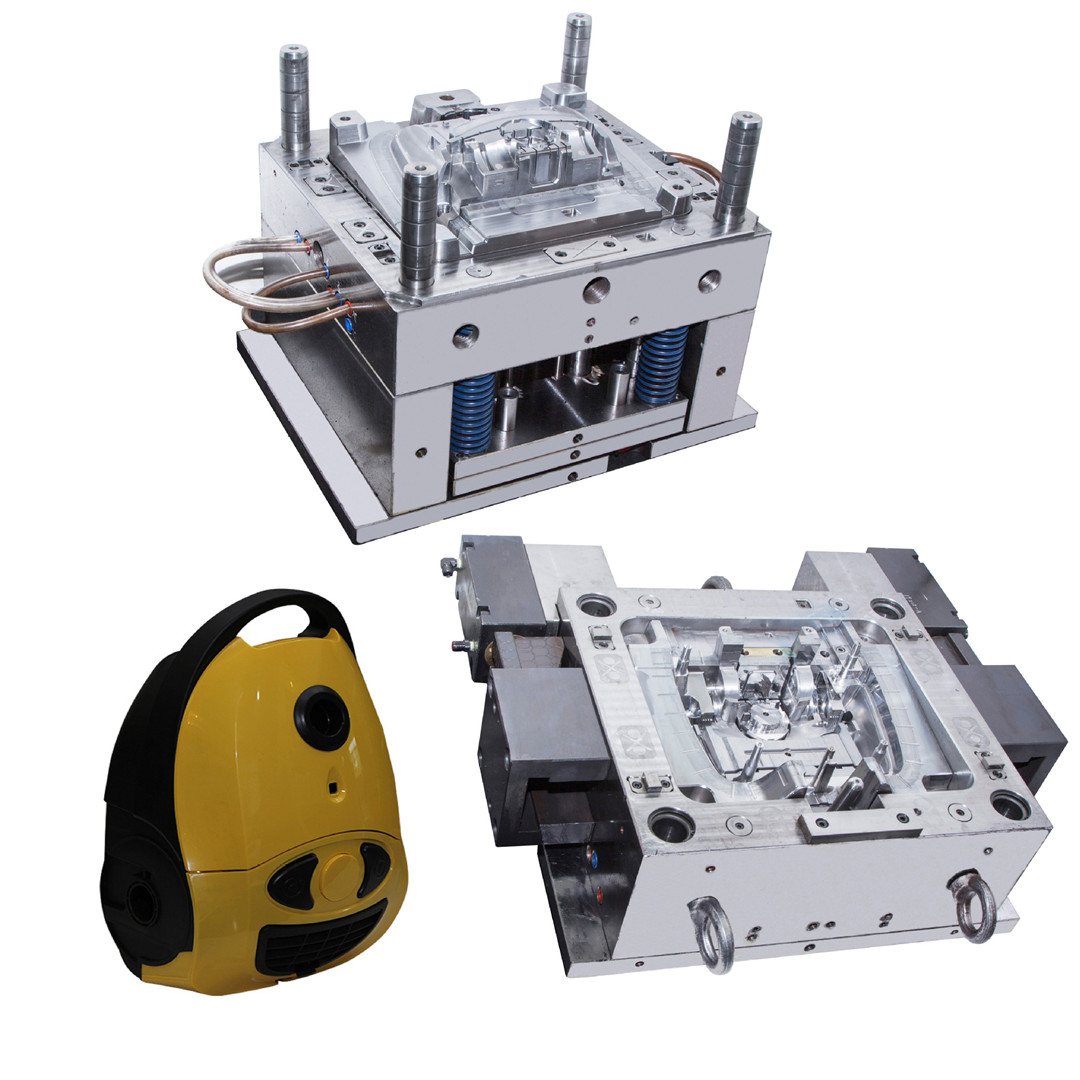

Plastic Jekiseni Mold

Plastic jekiseni molds aruminiyamu kana simbi molds anoshandiswa kugadzira zvikamu kubva kwakasiyana mapurasitiki, anosanganisira naironi, acrylics, elastomers uye inosimbisa zvinhu zvakaita segirazi-yakazadzwa polyamide.Zviumbwa zvepurasitiki zvinogadzika zvinogona kugara pakati pe10,000 ne1,000,000 shots.

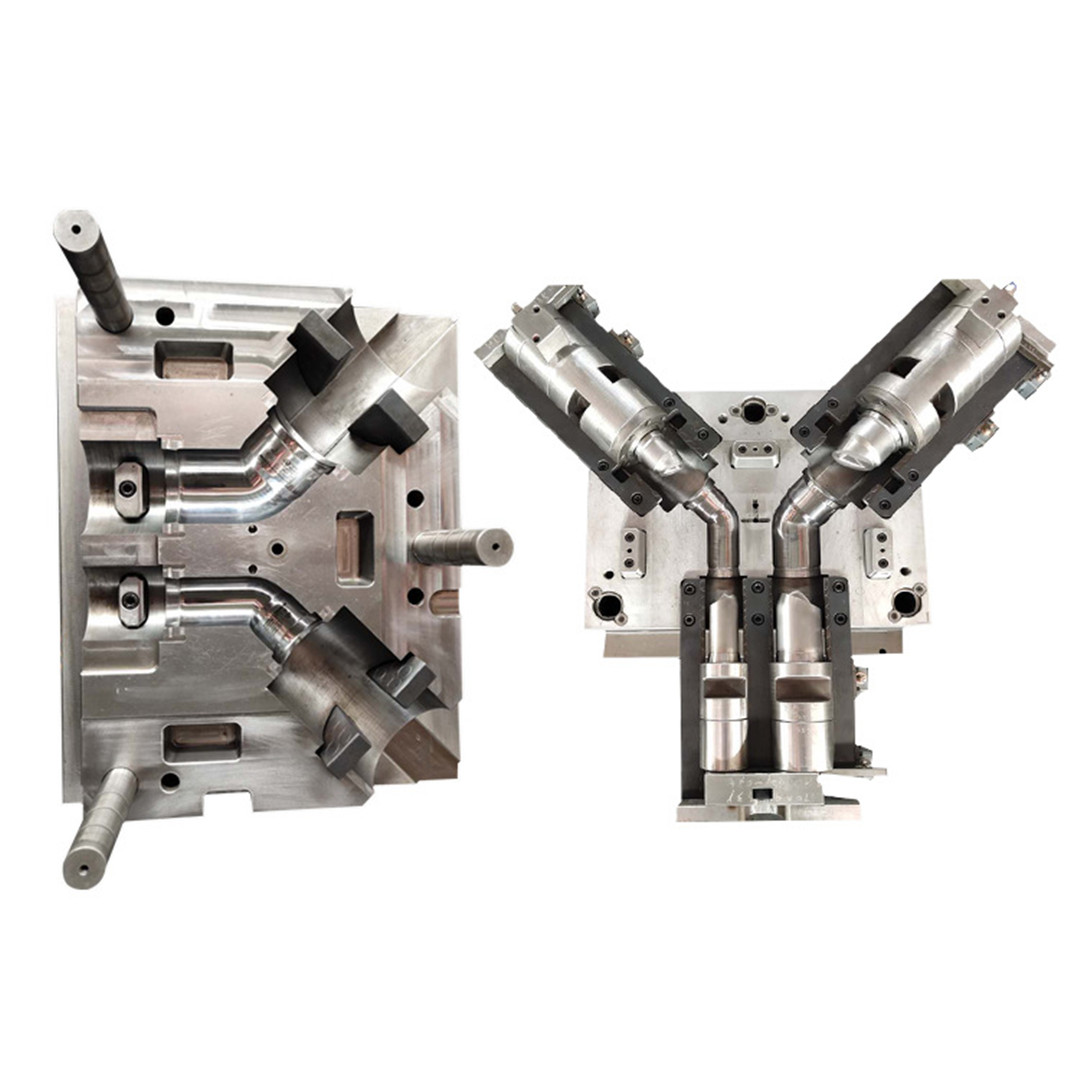

Mold Kugadzira Maitiro

Kugadzira mold inzira yakaoma inoda hunyanzvi hwepamusoro uye ruzivo.Kunyangwe nyaya yega yega yakasiyana, yakajairika kurongeka kweseti ye molds inogona kuenda seizvi:

1. DFM

Kana mutengi achinge asimbisa kurongeka kwe molds, isu tichatanga kuita ongororo yekutanga yezvikamu kuti tiwane pfungwa yechikamu mutsara, magedhi zvinzvimbo, nezvimwe.

2. Mold design uye mold flow analysis

Danho rechipiri rinosanganisira kushandiswa kwekufanotaura kwekufananidzira kwepurogiramu iyo inotibvumira kuona kuti zvinhu zvakanyungudutswa zvichabata sei kana ichipinda muhutu, zvichiita kuti pave nekuvandudzwa kwekugadzirisa.

3. CNC machining uye EDM

Isu tinogadzira ma molds ekutanga tichishandisa emhando yepamusoro machining midziyo, nepurasitiki, simbi, aluminium, nezvimwe zvakasarudzwa nemutengi.

4. T1 muenzaniso

Nezvichangobva kugadzirwa mold, tinoita T1 sampuli kuti tive nechiono chakajeka chekuti zvikamu zvekupedzisira zvakaumbwa zvemutengi zvichabuda sei.

5. Kuvandudza kana zvichidiwa

Zvichienderana nekuongorora kwedu kwemuenzaniso weT1, tinoongorora dhizaini yekugadzira uye kuita chero zvigadziriso zvinodiwa.

6. Tanga kugadzira uye kutumira

Isu tinogadzira molds maererano nezvinotsanangurwa zvekupedzisira tisati tazvitumira kune mutengi.