Chii chinonzi Jekiseni Molding?

Jekiseni molding inzira yekugadzira uchishandisa molds.Zvinhu zvakadai semasynthetic resins (mapurasitiki) zvinopisa uye zvinonyungudutswa, uye zvino zvinotumirwa kune mold kwazvinotonhodzwa kuti zvigadzire chimiro chakagadzirirwa.Nekuda kwekufanana nemaitiro ekubaya majekiseni emvura uchishandisa sirinji, nzira iyi inonzi jekiseni molding.Kuyerera kwemaitiro kunotevera: Zvishandiso zvinonyungudutswa uye zvinodururwa muforoma, uko zvinoomesa, uye zvino zvigadzirwa zvinotorwa kunze uye zvinopedzwa.Nekuumbwa kwejekiseni, zvikamu zvakasiyana-siyana, kusanganisira izvo zvine zvimiro zvakaoma, zvinogona kuenderera uye nekukurumidza kugadzirwa mumavhoriyamu makuru.Naizvozvo, kuumba jekiseni kunoshandiswa kugadzira zvigadzirwa uye zvigadzirwa mumhando dzakasiyana dzemaindasitiri.

Jekiseni molding inoshandiswa kugadzira zvinhu zvakawanda senge waya spools, kurongedza, mabhodhoro evhavha, zvikamu zvemotokari uye zvikamu, matoyi, mizinga yehomwe, zvimwe zvemimhanzi, macheya-chimwe-chidimbu uye matafura madiki, midziyo yekuchengetera, michina michina, mamwe akawanda epurasitiki. zvigadzirwa zviripo nhasi.Jekiseni molding ndiyo yakajairika nzira yemazuva ano yekugadzira zvikamu zvepurasitiki;yakanakira kugadzira mavhoriyamu akawanda echinhu chimwe chete.

Injection Molding Inoshanda Sei?

Star Machining inopa yakakwana yekugadzira mhinduro inovhara ese maficha ekusimbisa zvinhu, kugadzira maturusi, chikamu chekugadzira, kupedzisa, uye yekupedzisira kuongorora.Chikwata chedu chenyanzvi dzekugadzira chakazvipira kukupa iwe yepamusoro nhanho yerutsigiro rwehunyanzvi hwemajekiseni ekuumba masevhisi emhando ipi neipi kana kuoma.

Kazhinji jekiseni mold kugadzira kunogona kukamurwa kuita zvinotevera matanho:

1. Kuongorora maitiro ezvigadzirwa zvepurasitiki:

Pamberi pekugadzira mold, mugadziri anofanira kunyatsoongorora uye kudzidza kuti chigadzirwa chepurasitiki chinoenderana here nejekiseni rekuumba dhizaini, uye inoda kutaurirana nemugadziri wechigadzirwa nemazvo, uye kubvumirana kwasvika.Kusanganisira iyo geometric chimiro, dimensional kurongeka uye kutaridzika zvinodiwa zvechigadzirwa, nhaurirano dzinodiwa, edza kudzivirira kuoma kusingakoshi mukugadzira mold.

2. Mold structure design.

3. Sarudza zvinhu zvekuumbwa uye sarudza zvikamu zvakajairika.

Mukusarudzwa kwezvinhu zvekuumbwa, kunze kwekufungisisa kurongeka uye kunaka kwechigadzirwa, sarudzo yakarurama inofanira kuitwa pamwe chete nekugadzirisa uye kupisa kwekugona kwekugadzira fekitari.Mukuwedzera, kuitira kupfupisa kutenderera kwekugadzira, shandisa zvikamu zvemazuva ose zviripo sezvinobvira.

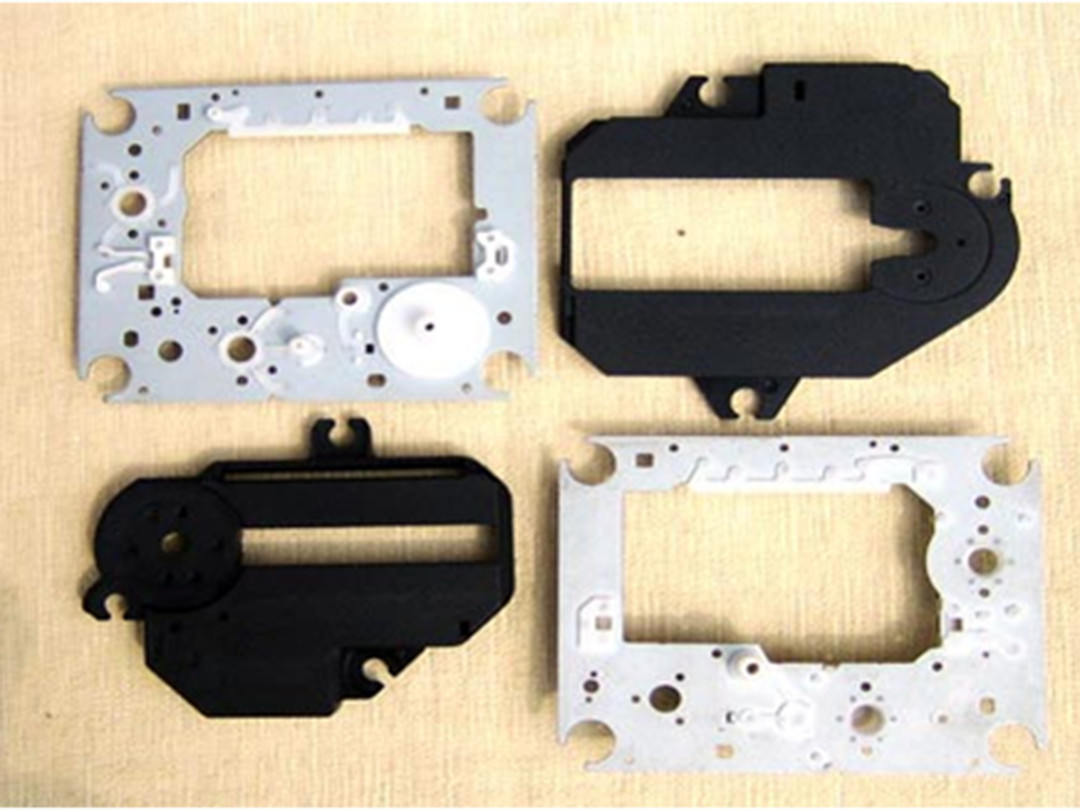

4. Zvikamu zvekugadzira uye mold musangano.

5. edza zviumbu.

Seti yezviumbwa inongopedza 70% kusvika 80% yeiyo yese yekugadzira maitiro kubva pakutanga kwedhizaini kusvika pakupera kwekuungana.Iko kukanganisa kunokonzerwa nekusawirirana pakati pezvakatemerwa shrinkage uye shrinkage chaiyo, kutsetseka kwekudzikisa, uye kutonhora kwemhepo, kunyanya kushandiswa kwehukuru, nzvimbo, uye chimiro chegedhi pamusoro pekururama uye kuonekwa kwechigadzirwa, inofanira kuva. yakaedzwa nemiedzo yeforoma.Naizvozvo, kuyedzwa kwe mold inhanho yakakosha yekutarisa kana mold inokodzera uye sarudza yakanakisa kuumba maitiro.

Jekiseni Molding Applicatons

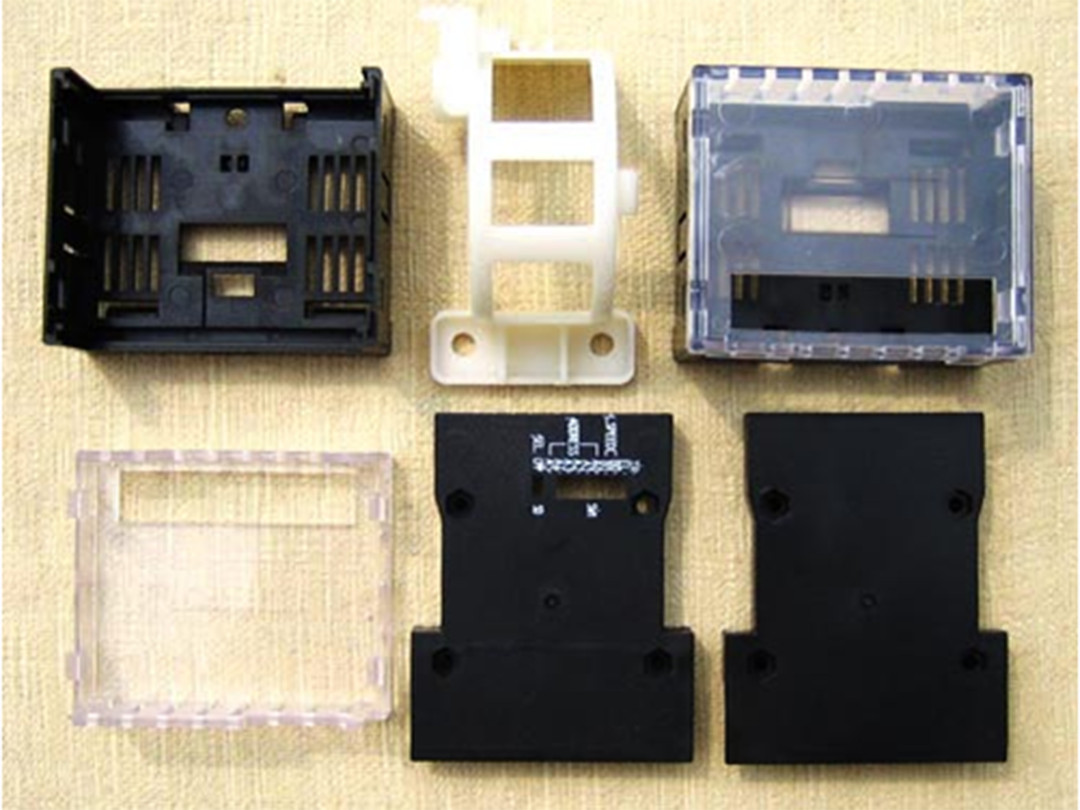

Jekiseni molding inoshandiswa kugadzira maumbirwo akaomarara ezvikamu zvemasaizi akasiyana ane kushomeka kwemadziro.Zvakajairwa zvikamu zvakaita sekapu, midziyo, matoyi, pombi dzemvura, zvinhu zvemagetsi, zvinogamuchira nhare, zvivharo zvemabhodhoro, zvikamu zvemotokari uye zvinhu.

Food and Beverage industry

Kana zvasvika pakuumba jekiseni, indasitiri yechikafu nechinwiwa inotsamira zvakanyanya pazvinhu zvepurasitiki kugadzira kurongedza kwechigadzirwa uye midziyo.Sezvo iyi indasitiri inofanirwa kutevedzera yakasimba sanitization uye mirairo yekuchengetedza, kuumbwa kwejekiseni repurasitiki kuri pachena kuti ive nechokwadi chekuti zvakasiyana-siyana zvinogadziriswa, kusanganisira BPA-isina, FDA-yakasimbiswa, isiri-chepfu uye GMA-yakachengeteka mitemo.Kubva kuzvinhu zvidiki semabhodhoro mavharo kusvika kumatireyi anoshandiswa muTV dinner, jekiseni rekugadzira rinopa imwe-stop-shopu yezvese zvekudya uye zvinwiwa indasitiri yekurongedza uye yemidziyo zvinodiwa.

Automotive Manufacturing

Indasitiri yemazuva ano yekugadzira motokari ichatora kuderedza huremu hwemuviri sechiyero chikuru chekuchengetedza simba.Munyika yose, huwandu hwemapurasitiki einjiniya mumotokari hwakaonekwa sechimwe chezviratidzo zvakakosha kuyera chiyero cheindasitiri yemotokari yenyika.Zvinotarisirwa kuti kukura kwemapurasitiki emotokari kuchave 10-20% mune ramangwana.Parizvino, huwandu hwepurasitiki inoshandiswa mumotokari dzepamba inongoverengera 5-6% yehuremu hwemotokari.Parizvino, indasitiri yekugadzira mota yeChina iri kuwedzera gore negore.Icharamba ichikwira gore negore mune ramangwana.Zvizhinji zvezvigadzirwa zvepurasitiki zvinoshandiswa mumotokari zvikamu zvakaumbwa majekiseni, senge kumberi nekumashure mabhampa, kumberi nekumashure mapaneru, mapaneru ezviridzwa uye zvishongedzo zvawo, mavhiri ekufambisa uye zvishongedzo zvawo, marara eradiator, mitsara yakawanda, uye mavara emarambi anosanganisa.

Jekiseni molding inzira yakadzikwa yekugadzira umo vanogadzira mota vanopinza zvinhu zvepurasitiki zvakanyungudutswa mumakomba ekuumbwa.Purasitiki yakanyungudutswa inobva yatonhorerwa yooma, uye mugadziri wacho anobudisa chinhu chapera.Kunyangwe iyo mold dhizaini yakakosha uye inonetsa (yakagadzirwa zvisina kunaka mold inogona kutungamira kune hurema), jekiseni kuumba pachayo inzira yakavimbika yekugadzira yakasimba mapurasitiki emhando yepamusoro.

Chishandiso Chepamba/Kuchengetedza Simba

MaTV eruvara, mafiriji, mahita emvura, muchina wekuwachisa, mabhatiri, maseru ezuva, magetsi ezuva, mabhokisi ekurongedza marara, matafura ekunze nemacheya, fenicha, tireyi hombe dzepurasitiki nemabhokisi ekuchinja, nezvimwewo. Zvigadzirwa izvi zviri kuuya kunzanga, zvakatarisana nekuchengetedzwa kwezvakatipoteredza. , yakatarisana nekuchengetedza simba, uye pane kudiwa kukuru kwezvigadzirwa zvekuumba jekiseni.Izvo zvinodikanwa kuti upe majekiseni ekuumba majekiseni ane hunyanzvi hwekuita uye mutengo reshiyo, zvimiro zvefoam jekiseni rekugadzira michina, microcellular foam jekiseni rekugadzira michina, uye akawanda-layer composite jekiseni rekugadzira michina.

Zvishandiso, zvemagetsi, IT, zvekurapa uye akangwara matoyi maindasitiri

Uyu musika mukuru wekuda unotongwa nediki uye micro jekiseni molding michina.Mundima iyi, michina yakawanda yekuumba majekiseni yakapinda mumhuri, kunyanya kugadzirisa mabasa akasiyana emotor, midziyo yemagetsi, zvinhu zvemagetsi, zvinobatanidza, machinjiro ekufambisa, akawanda anoshanda emagetsi nemagetsi akabatanidzwa zvigadzirwa, universal camera, camera instrumentation components. uye yakanaka ceramic zvikamu.

Infrastructure kuvaka inoda musika

Kusimukira kwenharaunda hakuparadzaniswe nekuvaka zvivakwa, uye chikamu chakakosha chekuvaka zvivakwa ndechekuvakwa kwepombi.Iko kugona kwemusika kweakasiyana jekiseni-akaumbwa pombi fittings uye zvishongedzo zvine chekuita nekuvaka, kudiridza, kuchengetedza mvura, kufonerana, tambo nemapombi zvakakura.Avhareji yegore yekukura kwemapombi munyika yangu ndeye 20%.Pakazosvika 2025, mapaipi epurasitiki achaverengera makumi mashanu muzana epombi yese, uye epakati nepakati uye yakaderera mapombi mumaguta achasvika 60%.Kana kudiwa kwepagore kwemapombi epurasitiki ari zviuru makumi masere kusvika zana zvematani zvichibva pamakumi mashanu muzana emapombi epurasitiki, zvinogona kutaurwa kuti kudiwa kwemusika muhombe wepombi dzemajekiseni, uye michina yekuumba jekiseni inogona kungogadzira jekiseni reUPVC nePE. pasi pe250-300mm.Pipe fittings.

Sei Sarudza Nyeredzi Machining yePlastiki Injection Molding

Iwo akanakisa ekugadzira mold maturusi anotanga nemhando yezvigadzirwa, yakasimba maitiro ekudzora, uye nyanzvi yekugadzira maturusi.Mutengesi chete ane makore ane ruzivo anotsigira Fortune 500 makambani anogona kuve nechokwadi chinodzokororwa mhedzisiro yezvako zvekugadzira zvishandiso zvekushandisa.Heano mamwe emabhenefiti ayo Star Machining anopa kune yakakwira-vhoriyamu yekugadzira maturusi ekugadzira uye jekiseni rekuumba masevhisi.

Masevhisi Akazara

Isu tinopa zvinopfuura kungoita maturusi ekugadzira uye kuumba masevhisi.Yedu yakazara pasuru inosanganisira ese ekugadzira maitiro aunoda kune yakazara chigadzirwa chekuvandudza mhinduro.

Proven Success

Zviuru zvemakambani ehukuru hwese kubva kutenderera pasirese vakasarudza kushanda neStar Rapid kuvabatsira kugadzira maturusi matsva ejekiseni uye zvikamu zvakapedzwa.Kubudirira kwako ndihwo hwaro hwemukurumbira wedu.

Positive Material Identification

Kuteerera kwako kwemitemo uye rugare rwako rwepfungwa zvinovimbiswa nedhipatimendi redu rinotungamira rekuzivisa zvinhu.Vanhu vanovimba neStar Rapid apo basa racho rinofanira kunge rakarurama.

Dhizaini Optimization

Dhizaini yakazara yekuongorora yekugadzira inouya nechero chishandiso uye chigadzirwa dhizaini purojekiti.Iwe uchagamuchira mibairo yepamusoro uchichengetedza nguva nemari.

Akangwara Makotesheni kune Yese Project

Isu tinotsigira zvibodzwa zvako zvebudiriro nekusava neashoma odha mavhoriyamu kana kukosha kwekugadzira kwedu jekiseni rekugadzira.Uye zvakare, isu tine yevaridzi AI inotora algorithm inopa nekukurumidza, kwakaringana, uye kwakajeka mitengo pane yega purojekiti, nguva dzese.

Ona mienzaniso yedu yekugadzira jekiseni